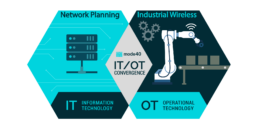

Efficiency is key to success. At mode40, we specialize in guiding companies through the digital transformation journey, empowering them to thrive in the era of Industry 4.0. Our mission is clear: to drive measurable value across the enterprise by seamlessly integrating engineering and technology to optimize manufacturing systems. Manufacturers rely on Programmable Logic Controllers (PLCs) to automate processes and streamline operations. However, to truly maximize efficiency and performance, it’s essential to have advanced PLC programming tailored to your specific needs. That’s where mode40’s PLC Programming service comes in.

What is PLC Programming?

PLC Programming is mode40’s specialized service that aims to maximize the efficiency and performance of your manufacturing operations and is one of the key pillars of mode40’s comprehensive approach to digital transformation. Our experienced team of PLC programmers specializes in driving transformative improvements in your production processes by seamlessly integrating advanced technologies and innovative strategies to improve throughput, reduce downtime, and optimize processes. we understand that maximizing efficiency and performance in manufacturing requires more than just technology—it demands a strategic alignment of people, processes, and technology.

How Does it Work?

Every manufacturing operation is unique, presenting its own distinct challenges and opportunities, that’s why we take a holistic approach to PLC optimization, focusing on aligning your existing processes and technological infrastructure with your overarching business objectives. Leveraging our expertise in engineering and technology integration, we conduct a thorough assessment of your manufacturing systems to identify areas for improvement. From there, we collaborate closely with your team to develop and implement advanced PLC programming solutions tailored to your unique needs and goals.

Our process begins with a comprehensive assessment of your manufacturing systems, drawing upon our expertise in engineering and technology integration. This detailed evaluation allows us to pinpoint areas for enhancement and process improvement, ensuring that our solutions are tailored to your organization’s needs.

Following the assessment, we closely collaborate with your team to develop and implement advanced PLC programming solutions. Whether your primary focus is on optimizing efficiency, improving reliability, or enhancing adaptability, mode40’s PLC Programming service is designed to empower your systems to perform at their peak level.

Why Choose PLC Programming by mode40?

- Advanced Expertise: As your partner in digital transformation, mode40 brings a wealth of experience and expertise to every project. Our seasoned team of PLC programmers is dedicated to driving transformative improvements in your production processes.

- Tailored Solutions: We understand that every manufacturing operation is unique, which is why we don’t believe in one-size-fits-all solutions. Our PLC programming solutions are customized to fit your specific requirements, ensuring maximum impact and return on investment.

- Transformative Improvements: By seamlessly integrating advanced technologies and innovative strategies, mode40’s PLC Programming service drives transformative improvements in your production processes, empowering your organization to achieve new levels of efficiency and performance.

- Efficiency, Reliability, and Adaptability: mode40’s PLC Programming service enables your systems to excel and perform in all aspects by seamlessly integrating advanced technologies and innovative strategies, we unlock the full potential of your manufacturing operations.

Customer Success Story: Driving Production Efficiency with PLC Optimization

In this case study, we delve into how mode40 partnered with a manufacturing client to tackle and overcome a crucial bottleneck and achieve remarkable improvements in their production process through strategic PLC optimization. Here’s a snapshot of how we helped one manufacturing client in the Food Industry.

Challenge: Our client’s production lines were hindered by a bottleneck upstream from their casepacker. Downtime in the casepacker segment led to missed opportunities for increased production.

Solution: We customized PLC controls to allow the filler to continue operating during casepacker downtime. Sophisticated monitoring and control mechanisms ensured seamless production flow and optimized Work in Progress (WIP) levels.

Impact: Our solution boosted daily production output by +5000 units and increased filler uptime by 12%, driving significant gains in operational efficiency and profitability.

Conclusion: Through strategic PLC optimization, mode40 empowered our client to overcome production challenges and achieve tangible improvements in their manufacturing operations.

Optimize Your PLC’s Today

Ready to revolutionize your manufacturing operations with mode40’s PLC Programming service?

Contact us today to unlock transformative improvements in your production processes and achieve new levels of success. Let’s propel your business forward into the future of Industry 4.0 together.

Reach out now to elevate your PLCs to drive efficiency, reliability, and adaptability to new heights with mode40 as your trusted partner.

Jon French

Technology Integration Expert | Manufacturing Problem Solver | 10x ROI